Here are the flanged copper-nickel tube plates for the 0-6-0 boiler. As you can see, the design is not a "standard" one - instead, I used the same ideas as for my 3003's boiler.

This time, I didn't bore the large flue holes on the lathe, instead I used my mill, the rotary table and a 6mm (1/4") end mill. Milling is much faster and easier than boring in the lathe, especially with a material like this - it's almost as "sticky" as pure copper!

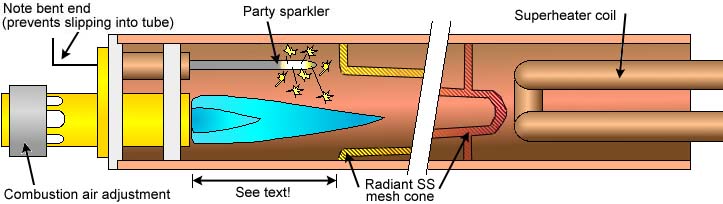

Since the flues are substantially larger in diameter (57 mm / 2.25") than on the 3003 (39 mm / 1.6"), I'm sure I'll be able to get all the heat I need with just two, instead of three propane burners as on the 3003 (design seen here). I'll see if I can come up with a piezo ignition that works reliably, instead of the sparklers...

Here's the still open front end of the boiler after I soldered the back head in place. Note the baffle on the dry pipe, almost touching the steam dome's bottom edge. There are two more baffles inside the dome - these three baffles will force the steam into a zig-zag path to prevent too much water splattering into the dry pipe. This is a slight problem with the 3003, if you aren't careful with the throttle.

Here we see the backhead of the boiler. I have slitted and bent out 25mm / 1" wide strips of the boiler tube's back end, to act as a fastening surface for the "cosmetic" backhead (which isn't even "on the drawing board", yet... ;-)

For the silver brazing, I used a Sievert torch with a propane consumption of 2 kgs (4.5 lbs) per hour - a lot of heat! For this reason I wasn't able to keep the flux and solder from flowing all over, not a pretty sight. But, since it will eventually be hidden, it really doesn't matter...

Another view of the boiler, this time from the front. There are 4 stay tubes, 10 mm (a bit over 3/8") in diameter, in addition to the dry tube and the large flues. The bushing in the center will take the feedwater connector. On the backhead end the center bushing will connect to the lower end of the water gauge.